What Does Biocompatibility Mean? 15 Biocompatible Materials

What is biocompatibility? In short, it’s how a material — known as a biomaterial — interacts with a living organism, referred to as a host. More colloquially, biocompatible materials are those used in medical devices within or touching the human body. The majority of products manufactured at Casco Bay Molding are made from biocompatible polymers for which lab testing results are available.

Which materials — metal and polymer — are biocompatible and what makes them so? What does it mean when something isn’t biocompatible? And what does testing entail? Whether you’re developing a product using biocompatible polymers or looking into medical device manufacturing more generally, here’s what you need to know.

DISCLAIMER: The following information is not medical advice. It was written for informational purposes only. If you have a medical question, please speak with your physician

5 Quick Facts About Biocompatibility

It is often used in reference to materials that do not produce a toxic or immune response within the human body.

Biocompatible materials are used in medical devices, such as a menstrual cup, stent, or ventilator.

Materials or devices are considered biocompatible only within their specific location within the human body and in relation to their specific application.

The term “Biocompatibility” is typically used to define polymers, meaning plastics, metals, and ceramics, though it can refer to devices that contain several materials.

Routine and methodical testing is required to be legally labeled as such. In the U.S., there is significant regulatory oversight from the FDA (Food and Drug Administration). Casco Bay Molding has been visited by the FDA regarding our manufacturing process. We passed our inspection without warnings.

Biocompatibility Definition

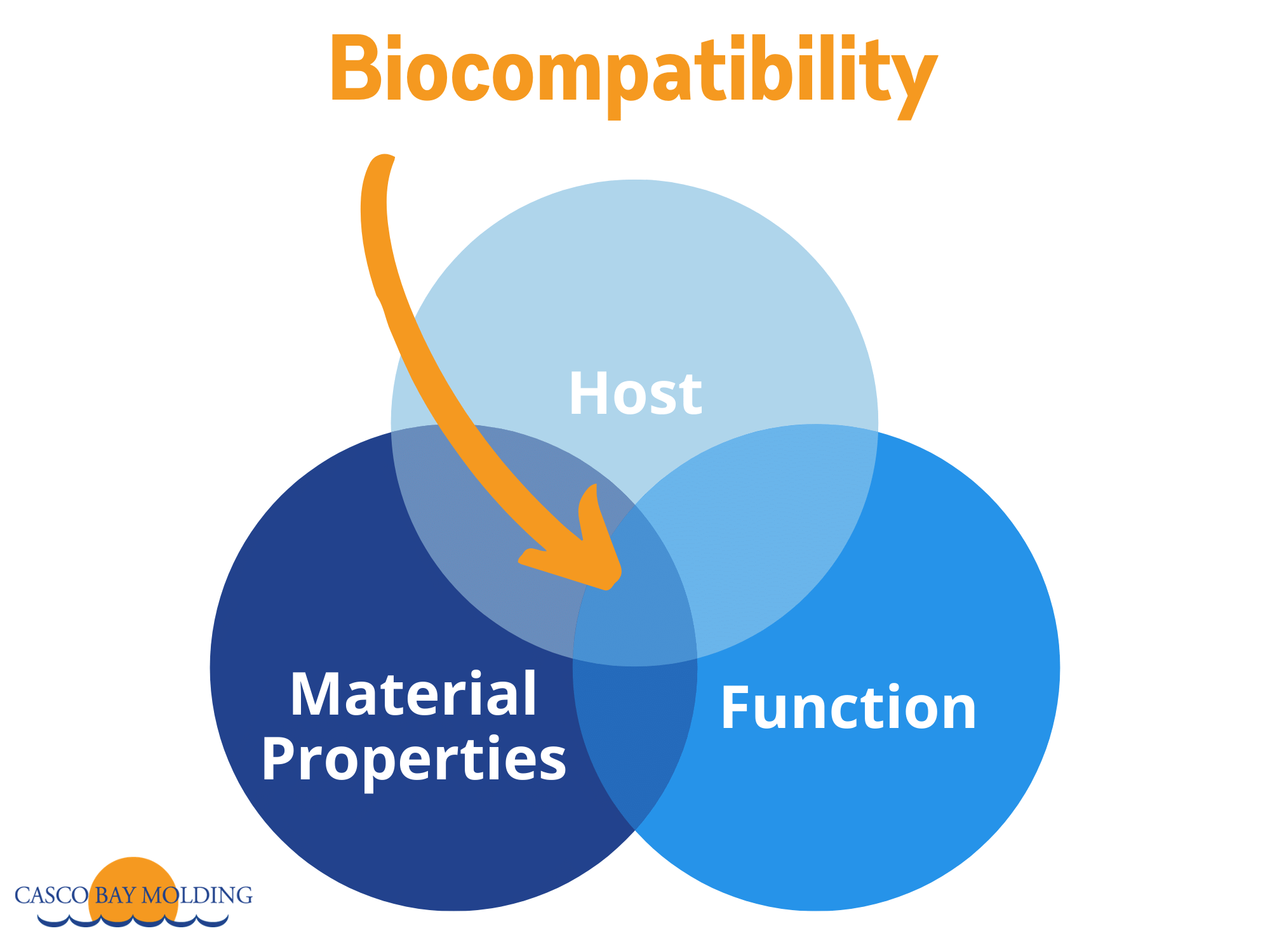

Simply put, it’s a material’s capacity to function with a specific application within a living organism.

This purposefully vague definition, taken from Materials Sciences and Engineering Reports, comes from continual research into what exactly is a biocompatible material. In short, it means that a material will not produce an immune response within the body.

Why Is It Important to Use Biocompatible Materials?

The human body’s immune system is designed to protect it from external attacks, including germs such as viruses, parasites, bacteria, and fungi. This sort of response can occur when a healthcare application uses a non-biocompatible material.

The human body’s immense system is complex, so materials can produce a toxic response in the short term, long term, or when combined with other materials. For that reason, biocompatibility testing is critical for all classes of medical devices.

Biocompatibility Testing Is a Varied, Complex, and Ongoing Process

In many cases, a medical device will involve more than one material and several rounds of animal testing and clinical trials. The more complex a medical device, the more important testing is. Testing typically involves three types of tests:

Analytical chemistry

In vitro testing

Animal testing

Analytical Chemistry: The Newest form of Biocompatibility Testing

The newest type of biocompatibility testing, analytics chemistry testing involves predicting material and device toxicity levels using existing data on chemical and material components, including existing in vivo data. This may involve considering the material — the effects of metals, polymers, colorants, and additives — and the chemicals that may leech from a material.

In Vitro Testing

In vivo, which translates to “within the glass,” refers to test-tube experiments, which occur in a laboratory. This is the process by which materials/device safety is tested prior to animal testing.

Animal/In Vivo Testing

Biocompatibility testing may involve animal testing, i.e. exposing an animal to materials or devices to test for an immune response. Though controversial, animal testing may help measure a few critical elements, according to the Food and Drug Administration:

How a medical device or material is broken down within a living organism

Whether blood absorbs a medication, and how much

A product’s toxicity level

A product’s metabolites, i.e. the components into which it breaks down

How and when a body excretes a product’s metabolites

In many cases, especially for complex applications, in vitro testing does not provide sufficient data: There are simply too many processes and variables within a living organism to account for without animal biocompatibility testing in many cases.

However, animal testing is not always required. For example, testing results for some commonly-used materials are already available. In other words, animal testing is typically only used when testing the biocompatibility of new materials or applications.

What Affects a Device/Material’s Biocompatibility?

There are three critical factors taken into account with biocompatibility testing:

The physical and chemical natures of a device’s material(s)

The human tissue that will be exposed to the material(s)

The length of the tissue’s exposure to the material(s)

Medical applications are not thought of as 100% biocompatible because the risk is never zero. It’s a question of how much risk is associated with a material. This is why some medical components are safe for short term use, rather than in long term.

15 Biocompatible Materials

Alumina (a ceramic biomaterial)

Bioglass (ceramic biomaterial)

Cobalt-chromium alloy (metal)

Hydroxyapatite (ceramic biomaterial)

Medical-grade silicone (short-term implantable and long-term implantable)

Polyvinylchloride (PVC) (polymer)

Polyethylene (PE) (polymer)

Polypropylene (PP) (polymer)

Polytetrafluoroethylene (PTFE) (polymer)

Polymethylmethacrylate (PMMA) (polymer)

Stainless steel

Trimethylcarbonate (polymer)

TMC NAD-lactide (polymer)

Titanium & titanium alloys (metal)

Zirconia (ceramic biomaterial)

Keep in mind that there are different levels of biocompatibility, notably short and long-term implantable. Additionally, materials are certified biocompatible depending on their location in the human body, duration of exposure, and combination with other materials. For example. some biocompatible silicon is suitable for short-term applications only. In other words, none of the above materials can be used for all medical applications or assumed to be biocompatible without extensive testing.

Disclaimer: Material biocompatibility can only be guaranteed by lab test results. Do not assume that all instances of the below-mentioned materials have been tested without seeing official lab results.

Understanding Silicone Biocompatibility

In recent years, silicone has become increasingly popular due to several advantageous properties. Not only is it soft, stretchy, and extremely challenging to break, but medical-grade silicone is biocompatible, meaning that it may be skin contact safe and/or safe to use inside the human body.

However, never assume silicone biocompatibility. If a material is not labeled as medical-grade and does not have traceability and biocompatibility certifications, do not assume that it is of healthcare grade quality. We frequently work with clients who believed that their previous manufacturers were using biocompatibility-tested silicone, only to discover that it is diluted with a filler. This is especially common with manufacturers in Asia.

Why Do People Mislabel Silicone?

Like many things, it comes down to price. High-quality silicone is expensive, therefore companies that are frequently not subject to U.S. regulations may be tempted to use fillers in their silicone. Introducing any sort of foreign element into even the most high-quality material is dangerous because it completely changes its nature. That’s why we only use medical-grade biocompatible silicone.

Our Approach to Silicone Biocompatibility

At Casco Bay Molding, we exclusively use 100% medical-grade silicone for our silicone products. Unfortunately, many companies may use fillers in their material to offset its price. By contrast, our silicone is medical-healthcare grade, Class VI. You can information regarding our biocompatible silicone in the certificates section of this site.

But producing skin-safe products requires more than silicone biocompatibility certificates. We are fully ISO:13485 certified, meaning that our practices—from product design to manufacturing to fulfillment—have been audited per medical-device standards. With regards to our menstrual cup business, we are also FDA-registered and successfully passed an FDA inspection.